Modern Tesla Model S collision centers face unique challenges due to the car's advanced technology and composite materials, requiring specialized tools and trained personnel. To provide top-notch repairs, these centers must invest in advanced training for technicians, state-of-the-art equipment like automated framing machines and CAD software, and continuous improvement strategies. This ensures accurate handling of intricate electrical systems, software diagnostics, and precise panel alignment, meeting the high standards set by Tesla owners.

The Tesla Model S, a flagship electric vehicle, has revolutionized the automotive landscape. However, its unique design presents significant challenges for collision centers. This article explores the impact of modern Tesla design on repair processes and offers insights from technicians. We delve into specific issues faced while repairing the Model S and propose strategies to enhance efficiency in handling these electric vehicles. Understanding and addressing these challenges is crucial for collision centers to cater effectively to Tesla owners.

- Understanding Modern Tesla Design and Its Impact on Collision Repair

- Unique Challenges in Fixing the Model S: A Technician's Perspective

- Strategies for Efficient and Effective Collision Center Operations with Tesla Models

Understanding Modern Tesla Design and Its Impact on Collision Repair

Modern Tesla designs, characterized by sleek lines, advanced technology, and innovative materials, present unique challenges for Model S collision centers. While these aesthetics enhance the driving experience, they introduce complexities in repair processes due to intricate structures and specialized components. For instance, the widespread use of lightweight composite materials in Tesla vehicles requires specific tools and expertise for effective dent removal and body repair, often diverging from traditional car manufacturing practices.

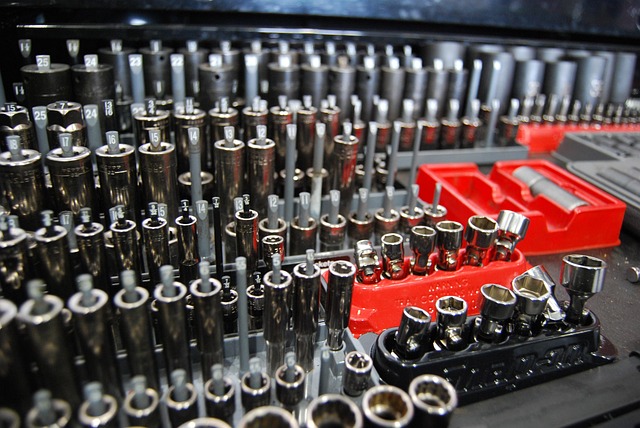

Collision centers specializing in Model S repairs must invest in advanced training and state-of-the-art equipment to accommodate these modern designs. This includes mastering techniques for intricate panel alignment, precise paint matching using computer-aided systems, and understanding the electrical systems integrated into Tesla bodies. Adapting to these challenges ensures that body shop services remain up-to-date and effective, catering to the needs of Tesla owners seeking top-notch repair experiences akin to those offered by Mercedes-Benz repair facilities.

Unique Challenges in Fixing the Model S: A Technician's Perspective

Fixing a Model S, while requiring advanced automotive skills, presents unique challenges for technicians at collision centers. Unlike conventional vehicles, Tesla’s intricate electric and software systems necessitate specialized knowledge to ensure proper repairs without compromising performance or safety. A simple fender bender can morph into a complex job when dealing with the Model S’s integrated motors, advanced sensors, and sophisticated computer systems.

Collision centers must invest in comprehensive training programs and state-of-the-art equipment to handle these intricacies, offering not just auto body services but also intricate automotive collision repair expertise. Technicians need to be adept at diagnosing issues that may not manifest as traditional damage, such as sensor misalignment or software glitches, to deliver top-notch repairs for this modern vehicle.

Strategies for Efficient and Effective Collision Center Operations with Tesla Models

In the realm of modern electric vehicle (EV) design, Tesla’s Model S has set new standards for luxury and innovation. However, this advanced technology also presents unique challenges for collision centers tasked with efficient and effective repairs. To meet these demands, collision centers must adopt strategic approaches that cater to the specific needs of Tesla models. One key strategy involves investing in specialized training for technicians, ensuring they are adept at handling the intricate electrical systems and software components unique to EVs. This includes understanding advanced diagnostics, battery pack repair, and the precise alignment required for autonomous driving features.

Additionally, collision centers should implement streamlined processes for vehicle dent repair and general car repair services, leveraging technology to enhance accuracy and speed. Automated framing machines and computer-aided design (CAD) software can aid in complex body repairs, ensuring precision and minimizing downtime. By combining these strategies with a focus on continuous improvement, Model S collision centers can deliver top-tier service, addressing the evolving needs of Tesla owners while maintaining high standards in vehicle body repair.

The modern Tesla Model S, while an innovative vehicle, presents unique challenges for collision centers due to its advanced design. As electric vehicles gain popularity, understanding and adapting to these specific repairs are crucial for efficient service. By implementing tailored strategies, collision centers can navigate the complexities of the Model S, ensuring quality repairs and customer satisfaction in this evolving automotive landscape. Optimizing operations for Tesla models is a game-changer, allowing centers to stay competitive and meet the demands of electric vehicle owners.